VolteraH2’s proprietary sealed electrolysis technology delivers numerous advantages over existing state-of-the-art solutions.

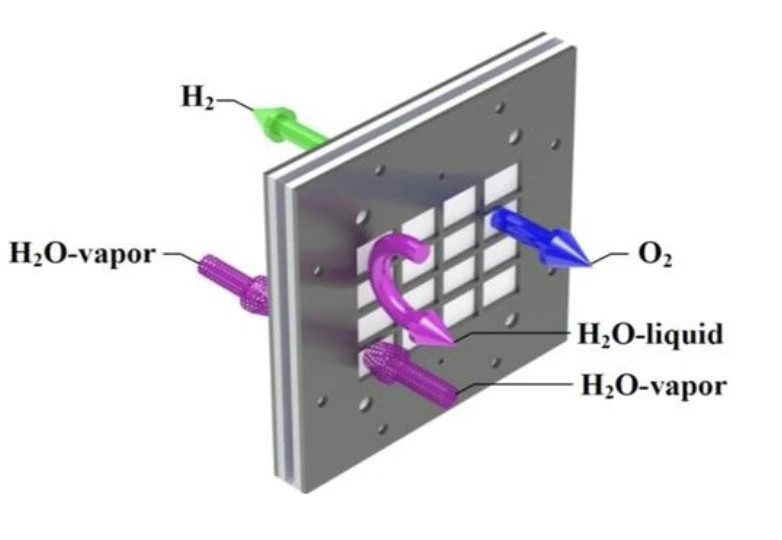

We’ve engineered a proprietary sealed electrolysis (SE) cell, an environment where the electrolysis process occurs. Our sealed cell offers superior energy efficiency, safety and cost-effectiveness, ensuring optimal operational parameters are maintained, especially with intermittent sources of electricity.

Advantages

By improving the electrical efficiency of the process and simplifying the balance-of-plant systems , the Sealed Electrolyzzer substantially lowesr the overall cost of producing hydrogen.

In SE electrolyte and electrodes are sealed and separated from the water feedstock and the electrolysis reaction is supplied by water vapor crossing interfaces. This allows SE to work with low quality water feedstock, even seawater, which has been considered a “holy grail” in the field.

Unlike traditional systems, SE doesn’t rely on Platinum Group Metals (PGMs), or other rare materials. Our sealed design protects metal components from corrosive KOH, permitting construction from affordable stainless steel.

Our electrolysis system operates under pressure, generating hydrogen that is already compressed. This reduces the need for hydrogen compression, saving energy and further reducing costs.

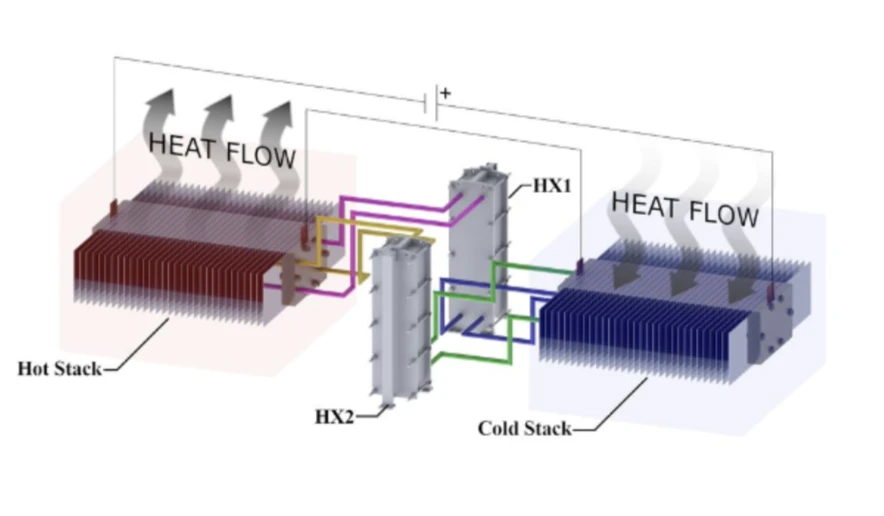

ColteraTREC is a breakthrough cooling technology, which will radically

change the way cooling is accomplished.

By eliminating the use of vapor-compression cycles, noxious refrigerants, and achieving energy efficiencies close to the theoretical maximum. ColteraTREC systems are lightweight, built from low-cost materials, and do not rely on any critical raw materials.

To learn more about ColteraTREC, see our website here.